P1 Technologies

P1 Technologies provides product design along with 3D printing, prototyping, and testing of your component requirements. As an ISO13485:2016 and ISO 9001:2015 certified manufacturer, P1 Technologies keep quality initiatives at the forefront of everything they do.

P1 Technologies do everything, so you don't have to. Partner with us and we will handle the details.

MEDICAL

Patient Monitoring Cables

We can design a medical cable assembly tailored to your needs, utilizing components from our extensive range of standard parts, or collaborate to develop a fully custom assembly unique to you. With over 600 wire options available and six million feet of wire in stock, we are well-equipped to create your specialized medical cable assembly. We prioritize the design, production, and reliability of quality connections, and our processes and products reflect this commitment.

Select P1 Technologies as your essential partner for medical product applications, including precision medical cables, interconnect products and systems, connectors, and accessories for diagnostic and monitoring needs.

Custom Interconnects

We love a challenge. Creating a custom molded cable assembly from a concept is our specialty. We partner with OEMs at the front end of development to create an overmolded cable assemblies that exceed expectations. Our team of R&D engineers work directly with our customers to develop working prototypes before low-high volume production. We have 39 dedicated insert molding machines and three automated wire cut/strip/terminating machines to bring your custom molded cable assembly to life. We also offer PCB fabrication, enclosures, and mating jacks.

Medical Injection Molding

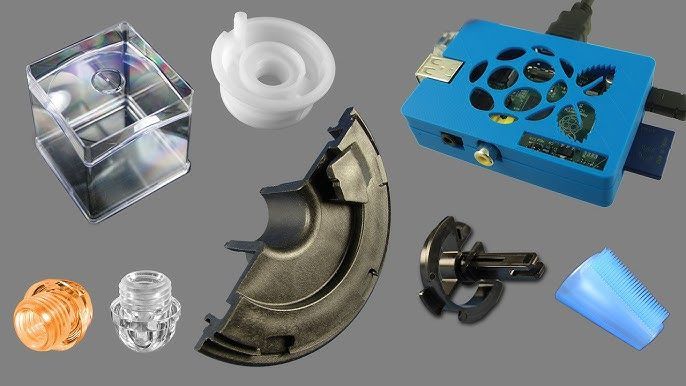

Medical injection molding, insert, and over-molding, can be tricky if you don’t have the necessary tools or expertise. Lucky for you, we’re the experts you’ve been looking for. We have everything you need under one roof in Roanoke, Virginia, so you don’t have to do anything if you don’t want to - we can even ship your product directly to the end user.

For product modification and new product development, we design, prototype, and build components from 1 gram up to 5 pounds. Our injection molding machines range from 15-ton to 310-ton capabilities.

If your medical part needs to be molded or assembled in a cleanroom, we’ve got you covered. We are certified to ISO 13485:2016 and ISO 9001:2015 standards and offer cleanroom molding and assembly to ensure your product is manufactured in a controlled and clean environment. The cleanrooms are certified to ISO Class 7 standards for sterile barrier packaging and ISO Class 8 standards for molding.

Explore metal-to-plastic conversion and take advantage of our skills in thin-wall horizontal, vertical, and turret molding with engineered and commodity resins. Run your molds here! If you’re not happy with your current injection molder, move your molds here, and we’ll start production of your parts seamlessly. We offer small quantity runs- as few as 100 pieces. If you want to do a test run to examine your parts in person, we can help. Make design changes quickly with our on-site toolroom. Our experienced toolmakers are ready to alter molds and retrofit existing molds to create a superior product.

AUDIO

In-ear Audio Monitoring

[Motion Series]

P1 Technologies developed the industry standard for IEM cables and connectors and has been making custom audio cables since the invention of the In-Ear Monitor. With our in-depth experience in the high-end audio field, we have created a “Motion Series” line of ready-made In-Ear Monitor cables. Based on the most popular components we offer, they feature an affordable price with reduced delivery time. High-Resolution Motion Series: made with high silver-plated stranded copper to produce a more detailed, crisp sound signature with tight bass.

High-End Audio

With more than 30 years of experience in the high-end audio industry, we truly understand the importance of quality, durable audio cables, and we create them. At P1 Technologies, we continuously design and innovate new audio products, including the latest connectors and high-quality, wearable wires. Our products have undergone rigorous field testing and have been embraced by numerous renowned and emerging performers, in addition to audio enthusiasts worldwide.

Audiology & Communications

P1 Technologies has been a part of the audiology industry for over 65 years. We specialize in Audiology, Communication, and High-End Audio, recognizing the uniqueness and diversity of each field. Our bone conduction cables and hearing aids provide the hearing impaired with the sounds of the world they have been missing, a responsibility we take seriously. P1 Technologies produces durable, custom communication cables, available in coiled or straight designs. We create tactical cables for military, fire, EMS, and police use, ensuring they remain reliable even after the race is won, the flames are extinguished, or the officer's shift ends.

DEFENSE

Defense Cables

Our dedication extends to supporting OEM customers in the development of mission-critical products and systems across military & aerospace industries. By leveraging our expertise and resources, P1 plays a crucial role in delivering innovative solutions that drive advancements in these vital industries, ultimately contributing to the safety and security of countless individuals worldwide. By overseeing every step of the manufacturing process internally, from design conception to packaging, P1 Technologies guarantees the highest standards of quality and precision.

P1 Technologies is International Traffic in Arms Regulations (ITAR) registered.

Custom Military Cable

Our commitment to vertical integration has enabled us to uphold strict control over the intricate manufacturing processes essential for industries as tightly regulated as medical, military, and aerospace. With a comprehensive range of in-house capabilities spanning from initial design to final packaging, P1 Technologies ensures a seamless and efficient production pipeline that adheres to the most stringent quality standards.

IN VIVO PRECLINICAL RESEARCH

We offer infusion cannulas, electrode systems, optogenetic components, and in vivo research necessities for study in the animal model including small animals (even neonatal mice) and large animals (non-human primates). We manufacture precision components you can trust so you don’t have to take time to make them yourself.

- Cannulas and cannula systems for single or bilateral injections.

- Electrodes and electrode systems for stimulation and recording.

- Optogenetic compatible components.

- Basic surgical mounting necessities.

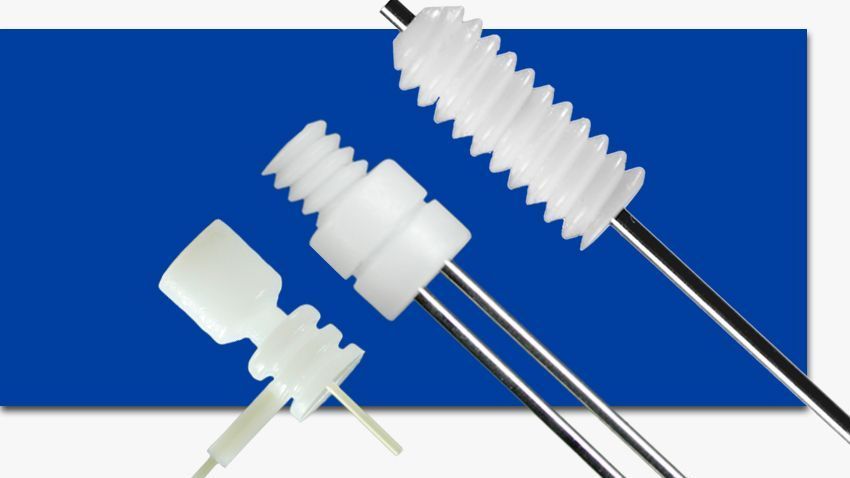

Cannula infusion systems

Infusion Systems are for short-term and chronic infusion studies of small and larger animals, these implanted cannulas deliver drugs, crystals, fluids, and fiber optics to specific sites in the brain.

In vivo Research Cannula Infusion Systems are ideal for acute and or chronic drug administration in animals of all sizes. These systems deliver drugs, crystals, fluid agents, and fiber optics to the researchers' specified location and are proudly made in the USA with the highest quality. With over 30 years of experience in the field of Neuroscience, our Cannula Infusion System is an industry-standard for researchers around the world.

Electrophysiology

In vivo Research Electrode Systems are ideal for acute and /or chronic electrical stimulation or recording in animals of all sizes. Our system is manufactured with assorted wire diameters and materials to meet the diverse specifications of all types of researchers. The Electrode Systems are proudly made with quality in the USA.

- Electrode: Stimulates or records activity within the animal.

- Custom Cable: Connect the electrodes with the researcher's data acquisition devices or neural stimulation devices.

- Commutators: (Electrical Swivels) To be used for acute or chronic studies.

Optogenetic Systems

Invivo Research Optogenetics is a relatively new technique that is starting to become more mainstream, and the possibilities are immeasurable. This type of research is allowing researchers the ability to turn specific neuronal circuits on and off by using light delivered through optical fibers. These light sources can be delivered to varying locations, such as the brain, spinal cord, or peripheral nervous system. Using P1 Technologies' Optogenetic Cannula System will help the researcher making delivery of the optic fibers to the neurons more accurate.

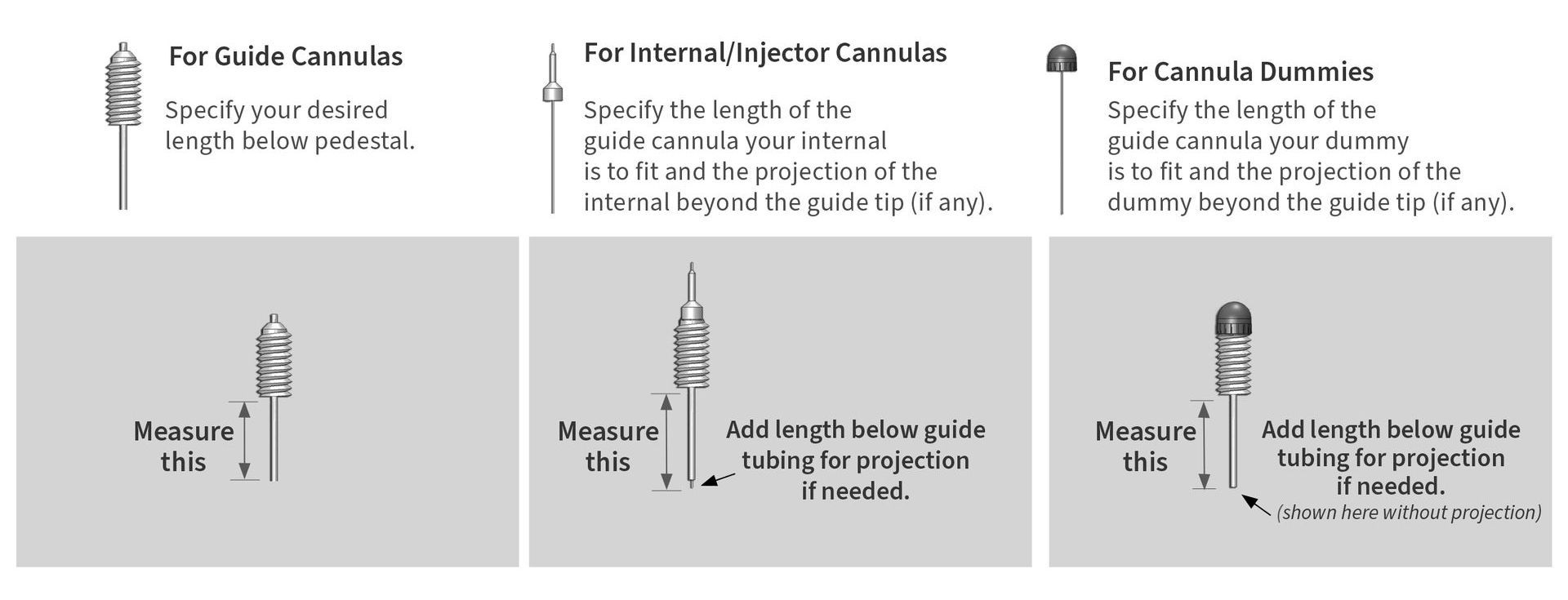

HOW TO SPECIFY CUSTOM LENGTHS

Guide lengths must be specified below the plastic pedestal. For internals and dummies:

Fit (LENGTH OF GUIDE) (GUIDE PART#) with a (LENGTH) projection.